All About Printed Circuit Board Layout Design

Here at Avanti Circuits, we are proud of the work that we do. We can create your ideal printed circuit board layout design so it works exactly as you need it to. A team of experts who have been working in the industry for almost 40 years, we’re trusted by some of the world’s biggest names.

We know what it takes to manufacture high-quality printed circuit boards. We also know how to keep all of our customers happy. You don’t need to work for one of the world’s biggest names to be happy with our products. We are here to help you no matter who you are or why you would like us to manufacture printed circuit boards for you.

If you would like to order some printed circuit boards or speak to us about our services contact us at 602-866-7227. We will be happy to speak to you about your PCB needs. When you work with us, you will be putting Americans to work. Our veteran-owned business is here to help you with your printed circuit board needs.

What Is A PCB?

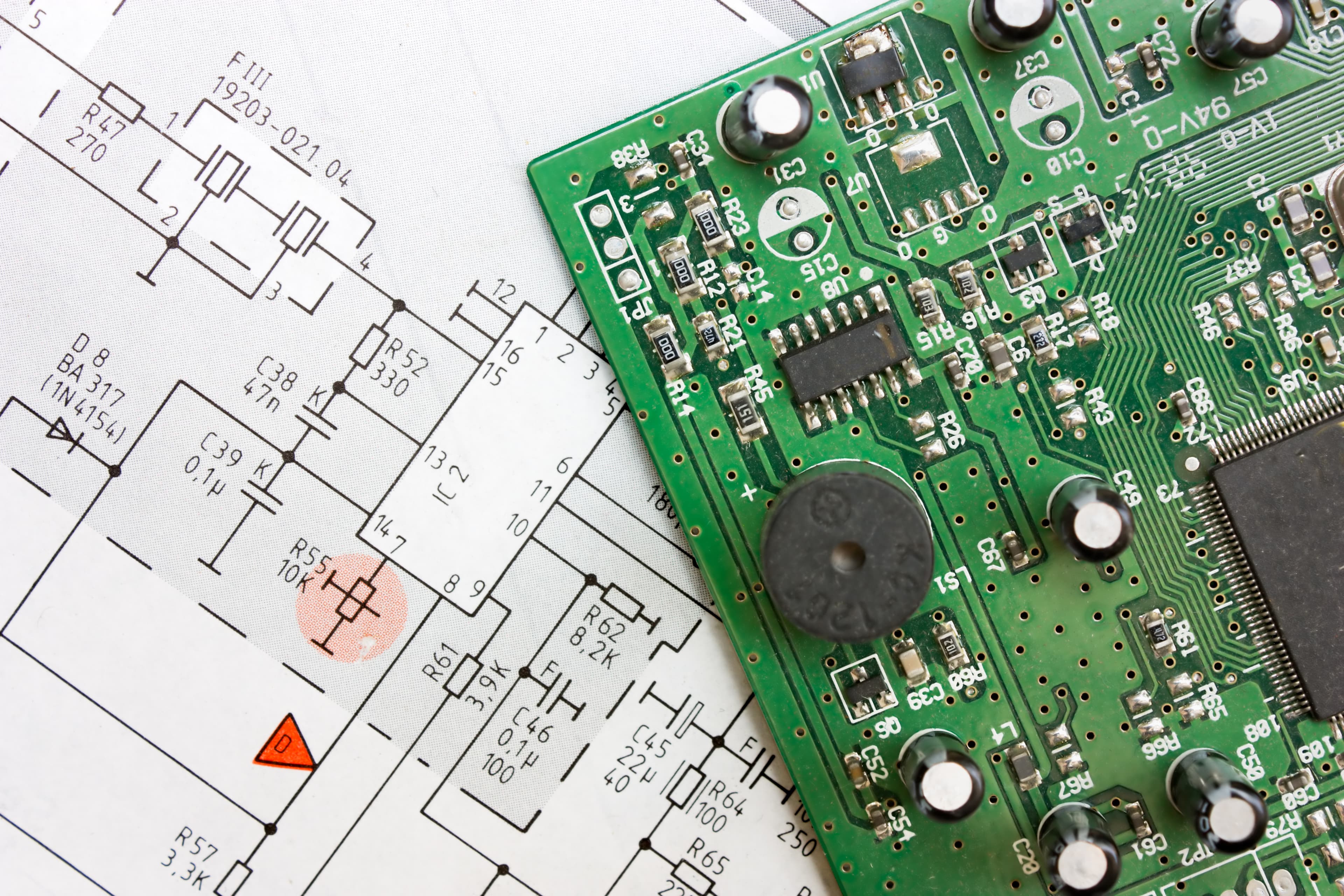

A printed circuit board is the name given to a board that comes with mounted electrical components. These electrical components use conductive pathways, signal traces, or tracks that are made from copper sheets. These copper sheets have been laminated onto the circuit board which is a non-conductive layer.

When the PCB has copper tracks and no components, it is often given the name “etching wiring board” or “printed wiring board”.

Printed circuit boards can help your electrical goods to work efficiently. Made up of a range of electrical components, PCBs are used in electrical products found in every household and every business in this country. Chances are, you’re never far away from a printed circuit board no matter where you are or what you do.

What Is PCB Layout Design?

PCB layout design refers to the design that helps to bring all of the PCBs electrical components to life. Using specific layout software, the design process combines routing and component placement to ensure there is electrical connectivity.

If just one of the components is misplaced or it is not accurately attached to the printed circuit board, the whole system can fail.

This is why, here at Avanti Circuits, we take a lot of care and time ensuring your PCBs are designed and manufactured with care. We are well aware that there could be many reasons why a printed circuit board fails to work as well as it should, if at all. This is where we can come in and make a real difference.

When you come to us with your design, we will check it thoroughly to make sure it works well. If we have any suggestions that may help to improve the design, we will let you know. We want all of your PCBs to work well every time. This is why we always check the design before the manufacturing process begins. In addition to this, once we have manufactured your printed circuit boards we will check them again. That’s right, we check each and every printed circuit board that we have made for you. We think it’s important that they work well for you, which is why we take time to make sure that they do.

About The PCB Design Process

The PCB design process begins by converting what is known as a “schematic diagram” into a circuit board layout. This can be quite a challenging process for some as theory needs to translate into a physical design.

– Orientation

Our engineers are here to do the hard work for you. They ensure that the diagram is translated so that it works as a circuit board layout. One of the first things that need to be considered is orientation. When components are placed on the PCB, they need to face the same direction. This is so that the board is much easier to manufacture and test. It also helps when your PCB is being inspected.

– In relation to other components

You will also need to consider how each of the components is being placed. While the direction is important, how they are being placed in relation to other components is also important. When your printed circuit board is being manufactured it will be put in a soldering oven. During this process, the solder will help to connect all of the components. However, if some large components are blocking the smaller ones, the solder joints may be poorly connected.

When you are designing your PCB, consider the height and width of each component.

– The routing

A lot of designers make the mistake of putting the components too close together. This tends to happen when an integrated circuit has a lot of pins that need connecting. However, if the components are not given enough space, you may need to start again. This is why it is important that designers consider what they will be routed to and how much space is required.

– The PCB Layout

As soon as the PCB design is complete, our engineers will start working on the layout. Please note, they will check the layout to make sure that everything is where it should be. This helps to pick up any errors that have been made. At this stage, errors can be adjusted so they are no longer an issue. If they are not found until a later time, it may mean that the PCB in question cannot be used effectively, if at all.

About Our PCB Layout Services

Here at Avanti Circuits, we are pleased to offer you our PCB layout services. These services are here to help you get the best printed circuit board for you or your client’s needs. We are proud of the work that we do to help all of our customers, and this is why we are happy to tell you about our printed circuit board layout services.

– Using our PCB layout tools

We can layout printed circuit boards in a variety of ways. We use a range of software tools, and we can work with any printed circuit board tool that you would like us to work with. Please contact us today if you would like to hear about our PCB layout tools.

– Using new or existing PCB layouts

Did you know that we can start a printed circuit board layout from scratch? Alternatively, we can use an existing design. The existing design can be supplied to you in a range of formats. We can use your own schematics or ours if you would like us to.

– Single or multilayer PCBs

We are happy to manufacture a wide range of printed circuit boards. We can provide you with a single layer, 2-layer, or even a 10+ layer printed circuit board that has impedance control. We can work with your layout to ensure that it suits the design. In addition to this, we will do what we can to keep your costs down. We will also provide you with designs that are compliant with IPC standards and guidelines.

– Gerber work

We can carry out front end Gerber work panelization, DRC checks, and more. Please feel free to ask us about our pre-production services. We can talk you through them and ensure you’re more likely to get what you need. Contact us today if you would like to talk. We’re a friendly, professional team that is here to help you.

– Board-level signal integrity

Out board-level signal integration ensures that many issues are quickly identified. We can identify noise, crosstalk, signal degradation, and more. We can also identify issues that are caused by coupling on your printed circuit board or electromagnetic interference.

– Our capabilities

If you are looking for a PCB manufacturer, we can help you. We can provide you with quick-turn PCB manufacturing. Our high-quality USA-made PCBs are second to none. As one of this country’s leading PCB manufacturers and suppliers, we know it’s very important that your PCBs are high-quality and delivered to you on time, every time.

We can offer you the following:

- Layers and base materials – 0-24 layers, 11 different base materials including Teflon, Arlon AR350, Rogers Ultralam 2000, and more. We also offer 4 different stiffeners and a range of final thicknesses, depending on how many layers your printed circuit boards have.

- Minimum and maximum thickness – Core thickness is a minimum of .0025”, and the maximum printed circuit board size we can offer you is 182 x 28” for a 2 layer PCB and a 16” x 26” for a multi-layer PCB. When it comes to using the finish plating, we can use 12 different types such as Immersion tin, Nickel flash gold, ENIG, Electroless soft gold, and more.

- Different sized layers – Our finished copper has outer layers that come in 3 different sizes from .004” for a 1oz Cu, and from .008” for a 3oz Cu. The inner layers come in 3 sizes, please ask us for details.

- Edges and types of solder mask – Our gold fingers have 1 to 4 edges, and we can use 3 different types of solder masks. We have a range of solder mask colors and 1 type of silkscreen which consists of thermal cure epoxy ink LPI ink.

- Silkscreen colors – We offer a range of silkscreen colors, CNC functions, in addition to conductive filled vias, tented vias controlled impedance, and more. Finally, we offer a range of tolerances, and quality, and testing. The latter ensures that all of the PCBs that we manufacture for you are more than good enough to work with your or your client’s products.

As you can see, we are capable of offering you more than many other PCB manufacturers. If you are unsure about anything that is listed above, please contact us. We’re here to help you with your questions and queries. We know what it takes to please our customers.

We are here to make sure that you are always happy with the PCBs we supply you with. In fact, we have very stringent quality control procedures. These procedures mean that you’re very unlikely to receive a PCB that has any faults.

We always check the design before the manufacturing process begins. In addition to this, once we have manufactured your printed circuit boards we will check them again. That’s right, we check each and every printed circuit board that we have made for you. We think it’s important that they work well for you, which is why we take time to make sure that they do. We take pride in the work that we do and we think you’ll understand why.

Contact Us today For A PCB Quote

We know you want the very best printed circuit boards for your money. This is why we are proud to offer you our printed circuit board layout design service and so much more. With almost 40 years in the industry, we can help you get exactly what you are looking for.

We can manufacture single layer, 2-layer, or even 10-layer PCBs and everything in between. We can work with you so you have exactly what you need when you need it. Sticking to our customer’s deadlines is something we’re proud to do. In fact, we try to beat those deadlines if we can. This ensures you get exactly what you need when you need it. Please note, even our quick turnaround PCBs are produced to the same high standards as our others. This means that you can order from us with complete confidence.

If you would like a PCB quote, please contact us at 602-866-7227. We always ensure that our quotes are as accurate as possible so you know where you stand. Contact us today if you would like to order high-quality printed circuit boards manufactured by an American company. We look forward to hearing from you.