PCB Material Manufacturers

Here at Avanti Circuits, we are proud to offer you high-quality printed circuit boards. With the world market for printed circuit boards thought to reach an estimated $79 billion by 2024, there is more demand than ever.

This is why pcb material manufacturers are finding that their products are needed more than ever before. We are one such manufacturer and we can help you with all of your printed circuit board needs. Contact us today if you want to learn how we can help you with your PCB needs. Call us at 602 866 7227.

What Are PCB Boards Made Of?

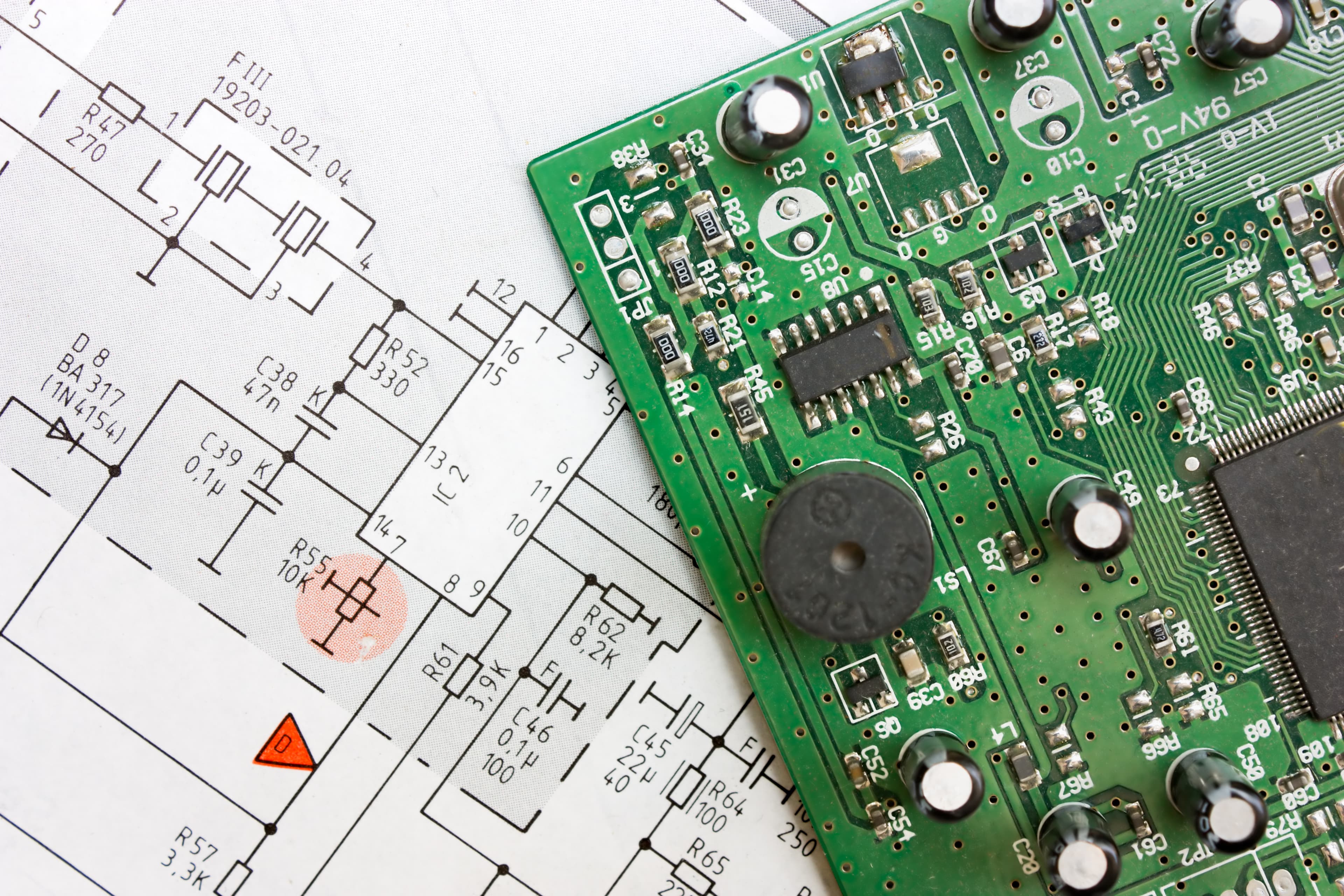

schematic diagram – design of electronic circuit and electronic board

Each printed circuit board is made up of non-conductive and conductive layers. These layers are bonded together so that they create one whole product. The materials that are used for each printed circuit board can be different depending on what the customer needs to use them for.

The typical materials that are used for a double-sided printed circuit board include:

- A silk print overlay that has component references

- A polymer varnish solder resist photo plot

- A copper or similar material that works as a conductive circuit

- A fiberglass epoxy resin, this is the unconductive rigid core

Double-sided PCBs which are also known as 2-layer boards can be comprised of

- A core layer – this is comprised of glass fibre-reinforced epoxy resin.

- A conductive layer – these layers are found on each side of the circuit board, and they help to make up the circuit as a whole.

Additional layers that are added before assembly such as

- A solder resist or solder mask – these are applied to help protect the bare conductive layer. Made of polymer ink, it can be screen printed using photoimaging ink or UV ink.

- A silk screen overlay or screen print – These layers are applied with very specialist ink that shows the component references and the symbol references. This is to help with the component location which is applied during the assembly process.

- Tin solder – this material is used when the PCB is being assembled. It attaches the components through surface mount pads or holes.

Suppliers Of PCB Materials

There are many different suppliers of PCB materials.

- Rogers Corporation located in Chandler, Arizona

- INSULECTRO located in Lake Forest, California

- ThermalWorks located in Santa Ana, California

- JMJ Profile Inc. located in West Berlin, New Jersey

- SABIC located in Pittsfield, Massachusetts

- Testco located in Windham, Maine

Some of the above suppliers offer more than PCB materials, whereas others simply offer an extensive range of PCB materials to the industry.

The Different Brands Behind PCB Materials

- Arlon – Based in Rancho Cucamonga, California, Arlon is a huge manufacturer of prepreg materials and performance laminate. The materials they manufacture are used in a wide variety of printed circuit board applications.

- Huazheng – Zhejiang Huazheng New Materials Co. Ltd, is just under 20 years old and is one of China’s oldest manufacturers of FR4 copper clad plate. With the ability to produce more than 1 million square meters of copper clad plate, the company also produces a range of products for the PCB industry.

- KB – With more than 60 branches, KB has extensive experience when it comes to producing a range of products. Starting off in the copper clad panel industry, this company is considered to be the world’s largest copper clad panel manufacturer.

- Lianmao – Located in Taiwan Province, Lianmao has more than 3,000 employees and is a major manufacturer. Providing its customers with all-round solutions, Lianmao considers itself to be a one-stop service.

- Nelco – RoHS compliant and with more than 50 years of global experience, this company produces a range of PCB materials such as polyamide, BT, and cyanate ester.

- Rogers – In business for almost 200 years, Rogers has headquarters all over the world. With the ability to manufacture high-performance materials, they constantly work to solve their customer’s challenges.

- Sy – Shengyi Technology is a global supplier of circuit base materials. With more than 30 years in the PCB industry, the factory now produces around 88.6 million square meters annually. Headquartered in China, the company employs nearly 10,000 people and has subsidiaries throughout Asia.

Types Of PCB Materials

There are 3 main types of PCB materials that are used during the manufacturing process. These materials are:

FR-4 – FR-4 is one of the most commonly used materials in PCB manufacturing. A glass-reinforced epoxy laminate sheet, epoxy is used simply because it is water resistant and flame retardant. In addition to this, it also provides very good strength to weight ratios. The tensile strength of this product is also known to be very good.

Metal – Metals such as aluminum, copper, iron, and others are still used in printed circuit boards. Materials such as these allow Surface Mount Technology to be used. This ensures that components can be integrated. In addition to this, the metals provide good mechanical durability. This means that metal base printed circuit boards tend to last a lot longer than others.

PTFE (Teflon) – A type of plastic that has no resistance is commonly used for high frequency and high speed applications. Known to be extremely flexible, PTFE is used for applications that have very tight tolerances. Lightweight, and with the ability to be used in a range of industries, PTFE has great physical strength, temperature stability, and flame resistance.

Each of these materials has its advantages and disadvantages. The material that is chosen for the task in hand is chosen with relation to the application required, environmental factors, and the results that are needed.

How these PCB Materials Are Used

– FR-4

FR-4 is commonly used because it is very low cost and versatile. It is considered to be ideal when it comes to manufacturing a small series of printed circuit boards. It can also be used to manufacture electronic prototyping.

– Metal

Metals are used in PCB manufacturing because they come with a lot of advantages. They are typically very cost-effective, and they can help to lower production costs. Some of the metals that are used in PCBs such as aluminum are easy to mine, thus helping to keep the costs down.

Another advantage of using metal is that they allow for heat dissipation. Heat dissipation can be a problem when manufacturing multi-layer and double-sided PCBs. Aluminum is typically used in a PCB as it’s an excellent conductor of heat, this means the PCB is less likely to over-heat. What this means is that you potentially have a PCB that will last a long time. Not only will this ensure your customers are happy, it can also help to boost your reputation as a reliable manufacturer. In some ways, this is priceless.

A third advantage of using metals in PCB manufacturing is that they tend to be very strong. They provide the PCB with a rugged base where fiber glass and ceramic may not. In addition to this, they can be very stress resistant and offer a good level of mechanical stability. What this means for the manufacturer is that they are less likely to be damaged while the PCB is being manufactured and while it’s being used.

The final advantage of using metals in a PCB is that they tend to be very lightweight. This is thanks to their low-density. In addition to this, the metals are recyclable and non-toxic and they are ideal for adaptable circuits. Finally, aluminum, for example, is quite flexible, offering even more durability. If you want to have a PCB that works well for you while offering reliability, you should seriously consider using metals in them where you can.

– PTFE (Teflon)

PTFE has very good dielectric properties which can be an advantage if you have high radio frequencies. This means that this material is ideal for use as an insulator when the PCB is used at microwave frequencies. PTFE also has a high melting temperature which means it is one of the best materials out there.

Many printed circuit boards do not contain pure PTFE. However, they do contain a very small amount that has been impregnated into the PCBs substrate. Alternatively, the PCB may contain PTFE that has been ceramic-filled or includes woven glass reinforcement.

When compared to other high-frequency materials, PTFE (Teflon), if it is almost pure and contains no woven glass, it can be one of the hardest materials to use in the manufacturing process.

Costs of These Materials

A microcontroller on an electronic board

The costs of the above materials can depend on where you order them from, how many you need, and what they are used for. Typically, the more materials you order, the lower the individual cost will be. For example, 10,000 orders for FR-4 will cost less per individual unit than 1,000 orders. If you have any queries about the cost of the materials and how they affect your order, please talk to us. You can reach us at the number found at the top or bottom of this article.

The good news is that you can keep the costs low if you know how. You can reduce assembly costs by:

- Using a drawing package that helps you to locate the components that you plan to use on the printed circuit board. This can help to reduce delays and ensure you’re much more likely to have the printed circuit boards you need with you before the agreed deadline.

- Working with your chosen manufacturer to make sure the finish you have cohen works well with the assembly process. In some cases, it might be ideal if you place the components that need specific locations before anything else. This is to ensure that you have enough space on the PCB for all of the components, especially those which are important.

- Trying to space out the components vertically and horizontally. You should also make sure that you orient similar components in the same direction whenever you can.

- Trying to minimize the length of the trace elements.

- Viewing the Gerber files using a separate viewer so you can see the files from a new perspective. Please contact us if you have any questions about your files. We can help you to design the best PCB for you and your needs.

- Considering hand assembly if you have a low volume run as this can be a more cost effective option for you when you only need a low number of PCBs.

- Considering automated assembly if you have a high volume run as it can be more cost effective. This is because the manufacturing process will be quicker.

- Keeping heavy, sensitive, or through-hole components on the main side. Also ensuring that components that require special attention are also kept on the main side.

All of the above tips can help you to keep the costs of the materials down. However, the cost that you’ll end up paying will be different depending on your chosen supplier, their skills, and their experience.

If you have any questions about the cost of manufacturing printed circuit boards, please contact us. We want to work with you so that you have high-quality printed circuit boards that work well for you. We are here to help you.

CONTACT US TODAY FOR PCB MANUFACTURING

While it is important to know that there are many different pcb material manufacturers in the country and indeed, around the world, finding a reliable one is not always that easy. The process of manufacturing printed circuit boards is complex and a specific set of skills and knowledge is required. This is where we can come in and help you. We can provide you with all of the printed circuit boards that you need. We are here to help you with all of your PCB inquiries and questions. Known to be one of the best printed circuit board manufacturers in the country, if you ask us to work with you, you will be putting Americans to work.

Contact us today if you want to learn how we can help you with your PCB needs. Call us at 602 866 7227. We will be more than happy to talk with you about your order and any queries that you may have. Contact us today so that we can help you.